The Lab Building of the Future is NEXT

January 25, 2022 | By Chad Yoshinobu

The demand for lab space and science workplaces is skyrocketing in almost every market, increasing competition among science building developers. The traditional method of designing new science buildings needs to evolve from what the building looks like, to how it needs to be optimized for a tenant. At their best, buildings are more than just containers for people; they are platforms for great efficiencies and incredible experiences.

Designing lab buildings comes with a raft of unique challenges. Concerns about vibration, ventilation, containment, and specialized equipment go beyond the scope of traditional workplaces. Developers must meet exact specifications to ensure safe and successful working environments for a variety of scientific endeavors.

The Next Generation of Science Buildings

As part of ongoing measurable impact research funded by the Gensler Research Institute, Gensler partnered with Buro Happold and KPFF to develop a conceptual framework for the next evolution of science buildings — how they will perform, and what they will look and feel like.

We located our concept in Seattle’s Uptown Arts District, and we based our decisions and design interventions around industry-specific research and data. The project had three goals: (1) liberate the space and make it more than just a container for people, (2) increase product differentiation in the market to allow our developer clients to leapfrog past their competition, and (3) offer solutions that prioritize decarbonization as a method of resiliency. We call this idea NEXT, and it redefines what a lab can be.

Using Mass Timber for Flexibility and Sustainability

The use of mass timber in large building construction has gained a lot of traction in recent years because of its ability to significantly lower the carbon footprint of a project. The material also has an emotional appeal because it lends warmth to a building’s interior; steel and concrete must be covered with extra material to achieve the same result.

We also discovered that timber is particularly suited to off-site modular construction, which would allow us to produce the project in a nearby factory and deliver it to the site as a kit of parts. This approach would be 30% faster and 10% cheaper to construct than a conventional concrete building. With 85% fewer deliveries to the site and a 75% reduction in construction waste, NEXT uses 80% less carbon to build than a conventional concrete lab building. This amounts to a savings of approximately 5200 total metric tons of CO2.

We extended the sustainable approach to the building’s operations, as well. NEXT uses an all-electric heat pump chiller (EL1) system that is more efficient than a natural gas system in all locations and sectors. All-electric systems result in lower building Energy Use Intensity (EUI) in all markets and achieve zero carbon emissions on a clean grid. In total, NEXT produces 50% less greenhouse gas emissions and uses 30% less energy annually than a conventional lab building.

Rethinking The Lab Layout

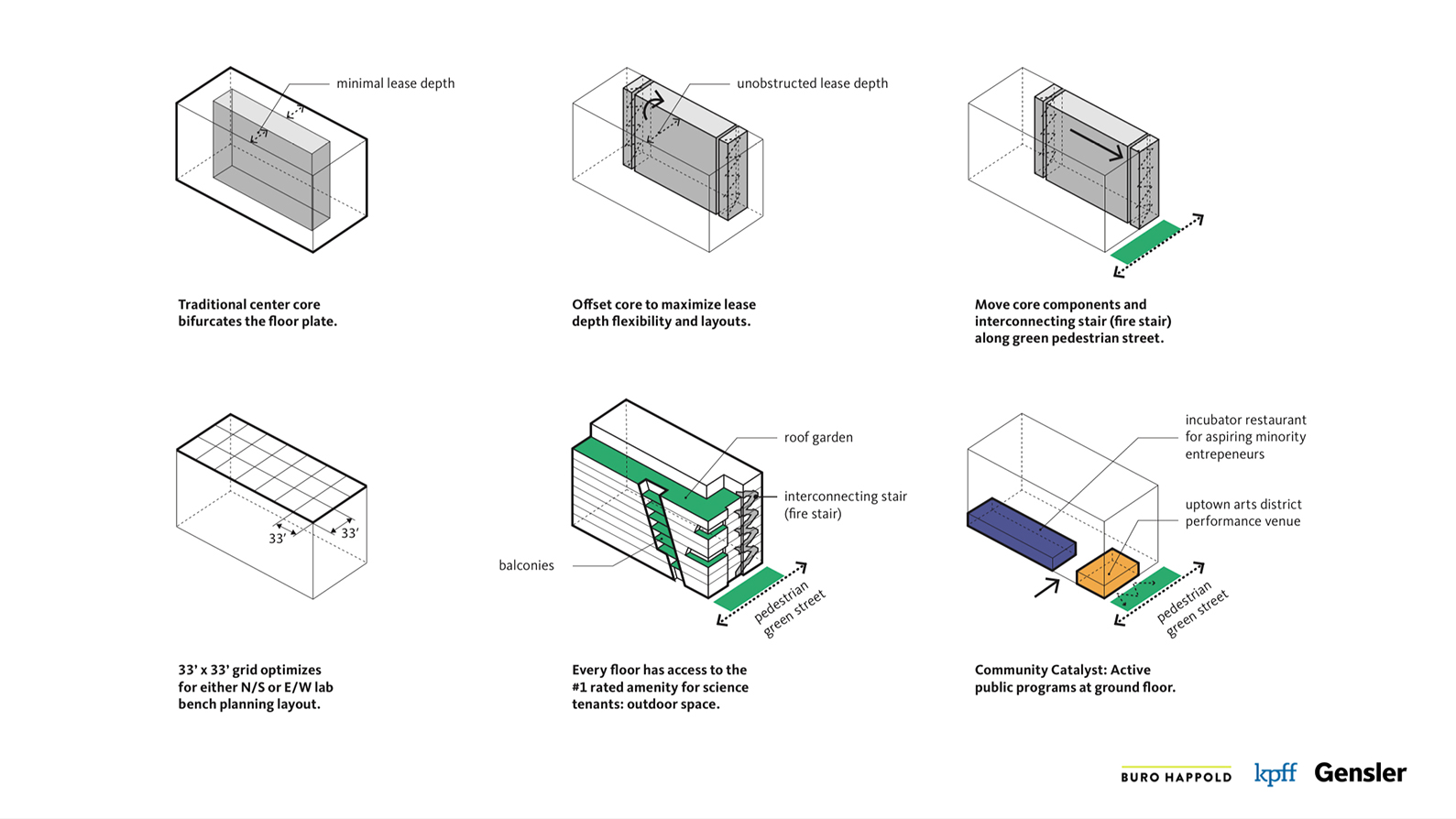

Another innovative feature of NEXT is the flexibility of the building grid. Lab building layouts are determined by two things: 1) the lab bench and 2) vibrations in the floor plate.

The lab bench is where equipment is stored, experiments take place, and work is prepped. It is a key building block of any science building. As for vibrations, they must be kept to an absolute minimum to prevent disruptions in science experiments.

We created the most flexible grid for our tenants at 33 X 33 feet. This is optimal for a lab bench layout because it allows our tenants to choose what’s best for them by orienting their lab bench north south or east west. However, the size of this grid in mass timber doesn’t work well with vibration, so we partnered with our engineering partner KPFF to make it work. Together we achieved a vibration of 6,000 MIPS, a go-to standard for most lab buildings.

We also relocated the building core from the center to the side of the building. Putting a core in the middle of a building is like putting a fireplace in the middle of your living room. It bifurcates and separates tenants. This move allows our tenants even more flexibility on their layout, without the obstruction of the building core hampering their options.

A Focus on Health and Wellness

Science workplace tenants are increasingly looking for spaces that can promote the health and wellbeing of their employees and of the communities in which they’re located.

NEXT puts a premium on natural ventilation and outdoor spaces. With a multitude of operable windows, the workplace portion of the floor will have abundant access to fresh air. And in Seattle, where the climate is optimal for natural ventilation, the workplace can spend 34% of total occupied hours in natural ventilation mode, which helps yield energy savings of 30% compared to a conventional lab building.

Each floor also has direct access to outdoor spaces that run up and down the building. According to the Gensler U.S. Workplace Survey, science workers ranked outdoor space as their #1 most desired workplace amenity. We also took the most under-utilized component of the building — a fire stair — and flipped it into a tenant amenity. We pulled the stair to the perimeter, flooding it with daylight and views.

This stair acts as a wellness amenity, liberating tenants from relying on elevators. Furthermore, with access control technology, this arrangement means the common stairwell can also act as an interconnecting stair for specific tenants on multiple levels — thus eliminating the need to build their own costly internal stairs, saving money, reducing unnecessary construction, and bringing the space to market sooner.

Connecting to the Community

Finally, we wanted to show how a science building could connect to its local community. The ground floor is designed to hold a multipurpose arts and entertainment venue as well as a restaurant incubator to diversify the culinary arts in the city.

The multipurpose venue was created in partnership with the Uptown Arts and Cultural Coalition (UACC) to provide flexible spaces for young musicians, art education, theater, and practice/performance space. The restaurant incubator gives minority entrepreneurs the opportunity to launch their businesses, while a shared kitchen space allows for multiple food venues to enhance the the neighborhood food scene. These efforts will create more cultural diversity within the Uptown District.

Ultimately, NEXT is a platform that allows tenants and developers to reimagine what a science building can be. In addition to delivering top-of-line functionality within the lab and workspace, NEXT offers opportunities for a variety of connections — to the outdoors, the community, and the surrounding cultural context — without sacrificing tenant flexibility. This is our call to action to shift from the past to a more resilient and inclusive future for lab buildings.

For media inquiries, email .